UT-Austin operates a 1.1 MW TRIGA II research reactor (with pulsing to a maximum permitted

reactivity addition of 2.2% Δk/k) at the J.J. Pickle Research Campus (PRC), approximately 10

miles north of the main campus in Austin, Texas. The reactor is located in the Nuclear Engineering

Teaching Laboratory (NETL), a building that

houses an organized research unit of the UT-Austin Walker Department of Mechanical

Engineering in the Cockrell School of Engineering. The NETL serves a multipurpose role, with

the primary function as a “user facility” for faculty, staff, and students from the College of

Engineering. The facility supports the Nuclear and Radiation Engineering Program of the

Department of Mechanical Engineering for laboratory exercises in UT courses, undergraduate

research, and graduate research. The NETL supports educational programs for other organizations

and institutions including Historically Black College and Universities as well as other Minority

Serving Institutions. The facility supports development and application of nuclear methods for

researchers from other universities, industry, and government organizations. The NETL provides

nuclear analytic services to researchers, industry, and other research and industrial laboratories for

testing and evaluation of materials. The NETL provides public education through tours and

demonstrations.

NETL Building: The NETL building is a 1950 sq meter (21,000 sq ft), facility with laboratory

and office spaces.

Building areas consist of two primary laboratories of 330 sq m (3600 sq ft) and eighty sq m (900

sq ft), eight support laboratories (217 sq m, 2340 sq ft), and six supplemental areas (130 sq m,

1430 sq ft). Conference and office space are allocated to twelve rooms totaling 244 sq m (2570 sq

ft). One of the primary laboratories contains the TRIGA reactor pool, biological shield structure,

and neutron beam experiment area. A second primary laboratory has walls 1.3 meter (4.25 ft) thick

for use as a general-purpose radiation experiment facility. Other areas of the building include

shops, instrument & measurement laboratories, and material handling facilities. An Annex was

installed adjacent to the NETL building in 2005, a 24- by 60-foot modular building. The annex

provides classroom space and offices for graduate students working at the NETL.

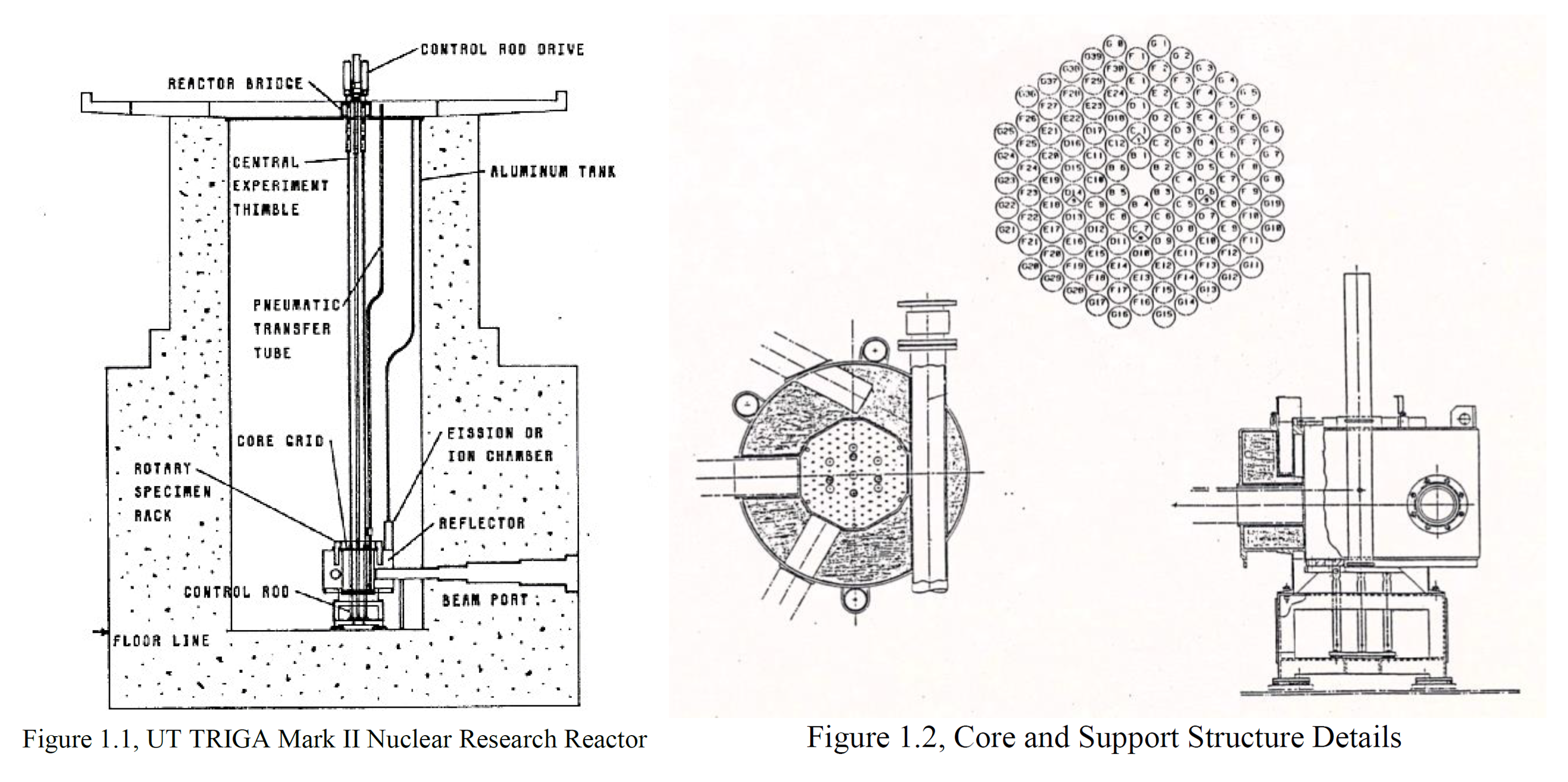

Reactor: The largest room in the NETL building is a vault-type enclosure that serves as a

confinement

volume for the UT TRIGA nuclear research reactor. The TRIGA Mark II reactor is a versatile and

inherently safe research reactor conceived and developed by General Atomics to meet education

and research requirements. The UT-TRIGA reactor provides sufficient power and neutron flux for

comprehensive and productive work in many fields including physics, chemistry, engineering,

medicine, and material science.

The NETL UT-TRIGA reactor is an above-ground, fixed-core research reactor. The reactor core

is located at the bottom of an 8.2-meter-deep water-filled tank surrounded by a concrete shield

structure. The water serves as a coolant, neutron moderator, and radiation shield. The

reactor core is surrounded by a graphite cylinder acting as a neutron reflector.

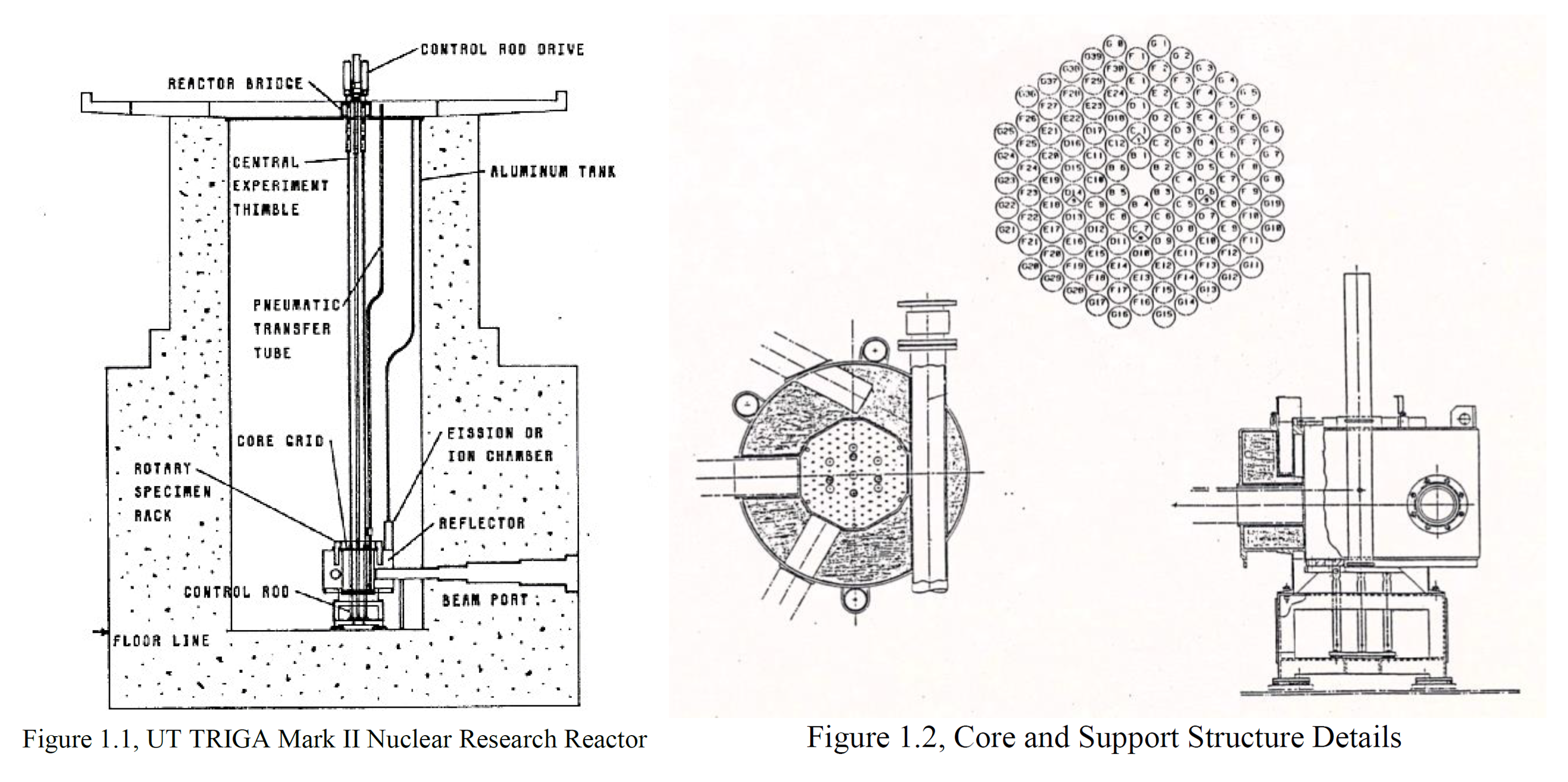

The reactor core is an assembly of cylindrical fuel elements surrounded by an annular graphite

neutron reflector. Fuel elements are positioned by an upper and lower grid plate, with penetrations

of various sizes in the upper grid plate to allow insertion of experiments. Each fuel element consists

of a fueled region with graphite sections at top and bottom, contained in a thin-walled stainless

steel tube. The fuel region is a metallic alloy of low-enriched uranium in a zirconium hydride

(UZrH) matrix. Physical properties of the TRIGA fuel provide an inherently safe operation. Rapid

power transients to high powers are automatically suppressed without using mechanical control.

The reactor quickly and automatically returns to normal power levels. Pulse operation, a normal

mode, is a practical demonstration of this inherent safety feature.

The reflector is a graphite cylinder in an aluminum-canister. A ten inch well in the upper surface

of the reflector accommodates an irradiation facility, the rotary specimen rack (RSR), and

horizontal penetrations through the side of the reflector allow extraction of neutron beams. In 2000

the canister was flooded to limit deformation stemming from material failure in welding joints. In

2004, the reflector was replaced with some modifications, including a modification to the upper

grid plate for more flexible experiment facilities.

The UT-TRIGA research reactor can operate continuously at steady-state powers up to 1.1 MW,

or in the pulsing mode with maximum power levels in the GW range for periods of up to ten milliseconds.

The pulsing mode is particularly useful in the study of reactor kinetics and control. The

power level of the UT-TRIGA is controlled by a regulating rod, two shim rods, and a transient rod.

The control rods are fabricated with integral extensions containing fuel (regulating and shim rods)

or air (transient rod) that extend through the lower grid plate for full span of rod motion. The

regulating and shim rods are fabricated from boron-carbide contained in stainless steel tubes. The

transient rod is a solid cylinder of boron-carbide clad in aluminum. Removal of the rods from the

core allows the rate of neutron induced fission (power) in the uranium-zirconium-hydride (UZrH)

fuel to increase. The regulating rod can be operated by an automatic control rod that adjusts the

rod position to maintain an operator-selected reactor power level. The shim rods provide coarse control of

reactor power. The transient rod can be operated by pneumatic pressure to permit rapid

changes in control rod position. The transient rod moves within a perforated aluminum guide tube.

The UT-TRIGA research reactor rod control system uses a compact microprocessor-driven control

system. The digital control system provides a unique facility for performing reactor physics

experiments as well as reactor operator training. This advanced system provides for flexible and

efficient operation with precise power level and flux control, and permanent retention of operating

data.